Casting

What Is casting?

Casting manufacturing is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed mold and allowed to harden. After solidification, the workpiece is removed from the mold to undergo various finishing treatments or for use as a final product. Casting methods are typically used to create intricate solid and hollow shapes, and cast products are found in a wide range of applications, including automotive components, aerospace parts, etc.

Different Types of Casting and the Casting Process

Sand Casting

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify.

Invesment Casting

When it comes to investment casting of metal parts manufacturing factors such as design requirements, cost, and feasibility to manufacture dictate which casting process is most suitable to manufacture a product.

Gravity and Pressure die casting

Gravity die casting is one of the oldest methods for metal or metal alloy casting. Here, the metal is poured inside the cavity in liquidus form using a ladle or a vessel. The cavity hole has to be on the top surface.

Sand casting

- WEIGHT RANGE:- 0.100 GRAM TO 250 KG ONE PIECE CAPACITY

- NEW DEVELOPMENT TIME PIRIOUD:- 30 DAY MAX. INCLUDED OF DESIGN AND DIE DEVELOPMENT AND PRODUCTION WILL SUBMITED TO 60 DAYS GAURENTEED

- METAL RANGE:- FERROUS AND ALL GRADES COSTOMER NEED WITH METAL CHECK CERTIFICATE (NABL LAB APPROVE)

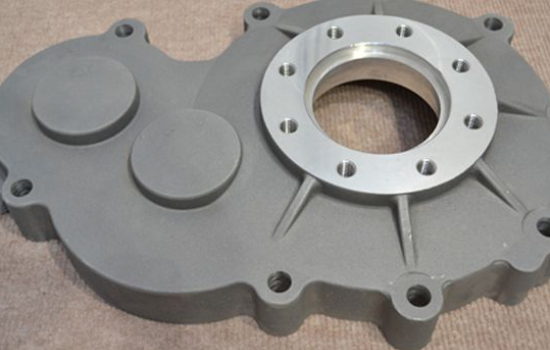

SAND CASTING PARTS WE SERVED

- AOUTOMATIVE PARTS

- MARINE PARTS

- COMPRESSORE PARTS

- BRACKING SYSTEM PARTS

- PUMP PARTS

- MACHINERY PARTS

- CONTRUCTION PARTS

- INDUSTRIAL PARTS

InvestMent Casting

- WEIGHT RANGE:- 0.030 GRAM TO 150 KG ONE PIECE CAPACITY

- NEW DEVELOPMENT TIME PIRIOUD:- 30 DAY MAX. INCLUDED OF DESIGN AND DIE DEVELOPMENT AND PRODUCTION WILL SUBMITED TO 60 DAYS GAURENTEED

- METAL RANGE:- FERROUS AND NON FERROUS AND ALL GRADES COSTOMER NEED WITH METAL CHECK CERTIFICATE (NABL LAB APPROVE)

INVESTMENT CASTING PARTS WE SERVED

- BALL VALVE

- GATE VALVE

- TAXTILE PARTS

- ELECTRIC CONDUCTOR PARTS

- CHEMICAL PUMP PARTS

- VACCUM PUMP PARTS

- SEA BOATING PARTS

- ENGINE PARTS

- ERTH MOOVER PARTS

Gravity And pressure die casting

- At first, heat the die and spray coating inside the cavity.

- Then melt the metal and convey it through a ladle. Note that if the casting machine is manual, then you have to pour the molten metal by hand.

- After that, slowly pour the liquid metal into the cavity.

- Then wait for it to solidify.

- Next, take out the part after opening the die.

- Finally, machine the part as necessary.

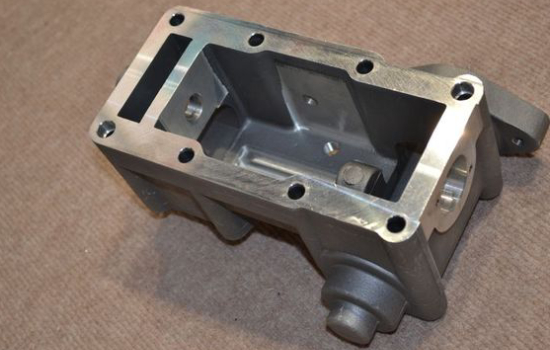

INVESTMENT CASTING PARTS WE SERVED

- BRAKE CALIPERS

- ENGINE PISTON

- HOUSING

- BASE MATERIAL

- KITCHEN POT

- SPOON